The rice milling machinery industry has experienced incredible achievements and advancements in recent years, revolutionizing rice processing and meeting the shifting demands of the global market. Technological developments have brought about a considerable transformation in the rice mill machine, improving its sustainability, quality, and efficiency.

Let’s talk about how the newest technology is altering rice production. We’ll study about environmentally friendly engines that speed up the production of rice. We’ll see in this blog how technology is significantly affecting something as basic as rice.

Knowing How Rice Is Milled

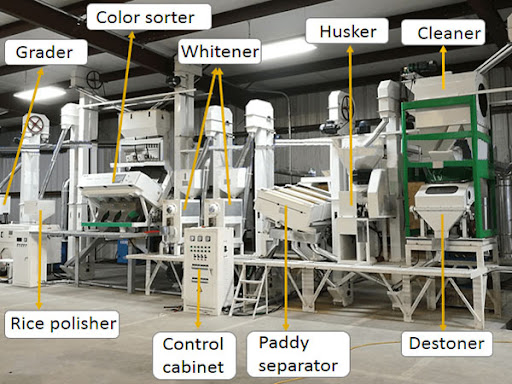

Before rice ends up on your dinner plate, it undergoes many changes. From the field to our kitchen, rice goes through several stages. Paddy rice, which is uncooked rice, is first thoroughly cleaned to get rid of any dirt, stones, or other unwanted items. This guarantees a tidy end result.

The hulling procedure follows. Think of paddy rice as a little nut with a hard shell. Carefully removing this shell, known as the husk, reveals the brown rice grain below. At this point, brown rice is fully edible, although it still has a nutty flavor and a little gritty texture.

The brown rice is polished to get the smooth, white rice that’s most often eaten. This method delicately removes portion of the grain’s outer layers, including the bran, using specialized technology. Although bran is full of nutrients, it shortens rice’s shelf life and makes it seem a little brown. The characteristic white, silky texture of rice sold in stores is the result of polishing.

The rice isn’t nearly done after polishing. It is carefully arranged according to size, color, and general quality. This guarantees uniformity in every box you purchase from the retailer. Kernels that are broken or have minor discolorations are kept apart for specific purposes. The final rice is then properly wrapped and served so you may enjoy it!

In order to complete this task quickly and efficiently, modern rice mills rely on sophisticated gear. It’s interesting to note that brown rice keeps more of its inherent nutrients than white rice while the bran layer is still intact. In light of your dietary requirements and preferences, you can select any of these two possibilities.

Developments in Rice Milling Equipment

New technological advancements have made it possible for any rice mill equipment to have automated features that increase milling precision. Higher-quality rice may now be produced by these machines, which can now precisely separate grains according to size, shape, and quality.

1. Robotics and Automation

Machines and robots are becoming crucial components of rice mills. They don’t need human assistance to do jobs like sorting, grading, and packing. This function saves labor expenses by making the operation of rice mill machines much simpler and more precise.

2. Technology for Precision Milling

Rice may be perfectly milled thanks to precision technology, which precisely modifies pressure, speed, and temperature. With the use of technology, we can be sure that rice is not wasted and that it tastes and looks fantastic.

3. The Efficiency of Energy

In all industries, including rice milling, sustainable practices are becoming increasingly important. Energy-efficient technology including solar power, biomass boilers, and heat recovery systems are used in modern rice mill machines. They can conserve energy and lessen their harmful effects on the environment.

4. Analytics and Digitalization

The way rice mills operate has changed due to technology. Modern software systems make it possible to monitor the milling process in real time, improving productivity and quality assurance.

Tools for data analytics look through large amounts of data to find trends, forecast equipment problems, and improve milling techniques.

5. Personalization and Adaptability

Modern rice mills come with a plethora of alternatives that can alter the needs of rice growers all over the world. The machines function properly and can do a wide range of activities effectively because they contain easily added or replaced elements.

6. Assurance of Quality

In the rice milling industry, quality control is essential. Through the use of sophisticated imaging technology, modern developments such as optical sorting systems make sure that only the best rice reaches customers by identifying and removing damaged grains.

7. Openness

Systems for monitoring food safety and transparency have become crucial in rice milling due to consumer demands. For instance, blockchain technology enables seamless tracking of rice from farm to plate, providing customers with crucial information on the provenance and caliber of the rice they eat.

Prospects and Opportunities for the Industry in the Future

With an increasing global population, there will likely be a progressive increase in the need for rice. The market for rice milling machines will continue to grow and innovate in order to sustainably fulfill this demand.

Thanks to developments in robotics, digitalization, and sustainability initiatives, rice milling has a bright future ahead of it in terms of increased output, quality, and environmental safety.

Obstacles in the Rice Mill Machine Industry

Although the rice milling industry offers numerous prospects, it also confronts many challenges. Keeping ahead of the curve requires constant innovation and adaptation to changing market conditions due to the fierce competition.

In an ever-changing business, manufacturers may set themselves up for success by utilizing emerging trends and overcoming challenges.

The rice mill machine industry will continue to evolve and adopt new technologies driven mostly by innovation and sustainability.

In summary

In addition to revolutionizing the rice processing sector, technological advancements in rice milling equipment will also have an impact on future global food production.

Rice mills are equipped to use automation, precision technology, sustainability, and digitization to solve the issues of the twenty-first century and beyond.

As people grow more conscious of what they eat, the rice milling industry’s commitment to sustainability, quality, and transparency will undoubtedly have a significant impact on the future of food.